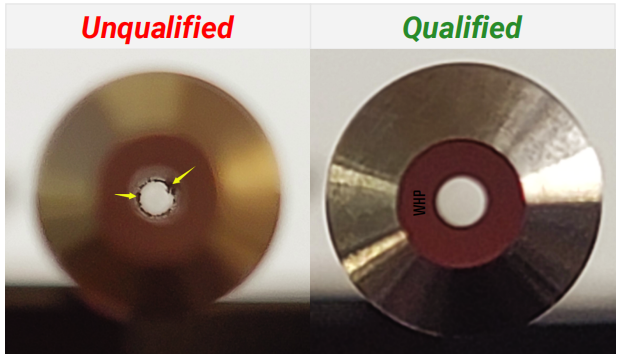

Every time when you replace with the new nozzles, you’d better have a visual inspection before installing it.

Operating:

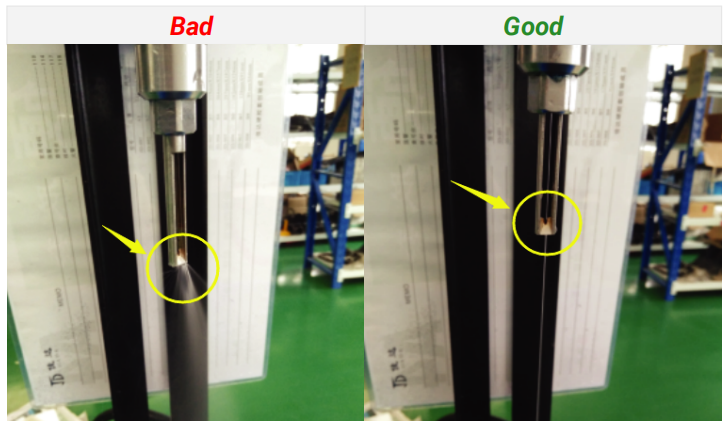

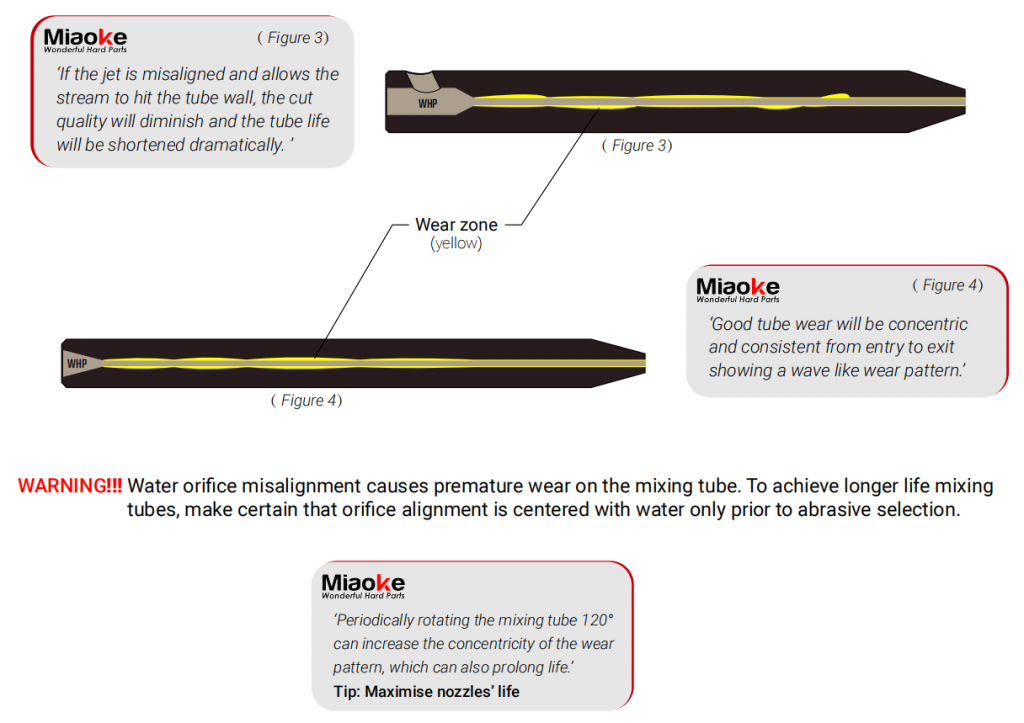

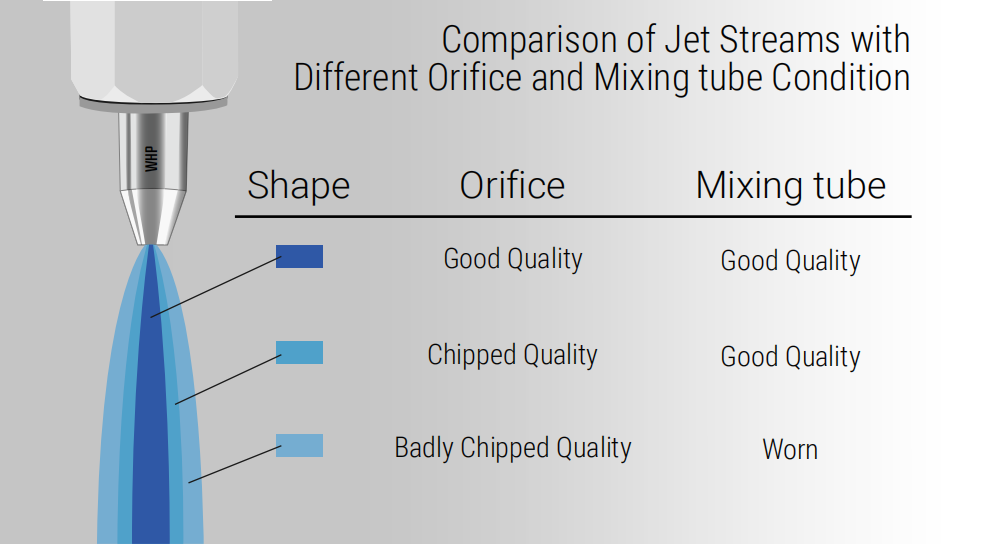

"WHP Alignment Scout is launched to solve this problem. Usually When a waterjet nozzle wron, we don't know if it's the problem which caused by orifice or some other parts of the cutting head. Alignment Scout can help you adjust the misalignment between the orifice and the mixing tube."

Miaoke Precision